<a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg:: ::/sites/dl/free/007242155x/69909/chap14intro_figure1.jpg','popWin', 'width=400,height=505,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (52.0K)</a> <a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg:: ::/sites/dl/free/007242155x/69909/chap14intro_figure1.jpg','popWin', 'width=400,height=505,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (52.0K)</a> | |

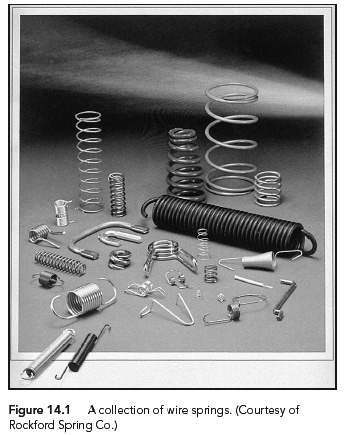

Springs are used to exert forces or torques in a mechanism or primarily to store the

energy of impact loads. These flexible members often operate with high values for the

ultimate stresses and with varying loads. Helical springs are round or rectangular wire,

and flat springs (cantilever or simply supported beams) are in widespread usage. Springs

come in a number of other kinds, such as disk, ring, spiral, and torsion bar springs.

Numerous standard spring configurations are available as stock catalog items from spring

manufacturers. Figure 14.1 shows various compression, tension, and torsion springs. The

designer must understand and appropriately apply spring theory to specify or design a

component.

Pneumatic springs of diverse types take advantage of the elastic compressibility of

gases, as compressed air in automotive air shock absorbers. For applications involving very

large forces with small displacements, hydraulic springs have proven very effective. Our

concern in this text is only with springs of common geometric form made of solid metal or

rubber. For more information on others, see [1-5]. As discussed in Section 1.4, mechanical

components are usually designed on the basis of strength. Generally, displacement is of

minor significance. Often deflection is checked whether it is reasonable. However, in the

design of springs, displacement is as important as strength. Anotable deflection is essential

to most spring applications. |