|

| 1 |  |

In 1987, Congress established __________ to enhance the competitiveness of U.S. businesses by promoting quality awareness, recognizing quality and performance achievements, and publicizing successful performance strategies of U.S. organizations in the areas of manufacturing, service, and small business. |

|  | A) | ISO 9000 |

|  | B) | ISO 14000 |

|  | C) | the Governance Performance and Results Review Board |

|  | D) | the Cost Accounting Standards Board (CASB) |

|  | E) | the Malcolm Baldridge Award |

|

|

|

| 2 |  |

_______________ is the set of standards that relate to environmental management. |

|  | A) | the Malcolm Baldridge Award |

|  | B) | ISO 9000 |

|  | C) | ISO 14000 |

|  | D) | ISO 9002 |

|  | E) | ISO 10000 |

|

|

|

| 3 |  |

Which of the following effects is not likely associated with improved quality? |

|  | A) | Increased financial returns (e.g., as measured by ROI). |

|  | B) | Reduced levels of inventory. |

|  | C) | Reductions in total manufacturing cost. |

|  | D) | Increased product returns. |

|  | E) | Both "B" and "D." |

|

|

|

| 4 |  |

Which of the following is a financial tool that can be used to manage and control quality? |

|  | A) | cost of quality (COQ) reporting framework. |

|  | B) | the balanced scorecard. |

|  | C) | six sigma performance reviews. |

|  | D) | Total Quality Management (TQM). |

|  | E) | None of the above. |

|

|

|

| 5 |  |

Six sigma is based on a problem-solving methodology known as: |

|  | A) | DMACC. |

|  | B) | DELAY. |

|  | C) | DMAIC. |

|  | D) | DRIM. |

|

|

|

| 6 |  |

Goalpost Conformance refers to: |

|  | A) | A range of conformance to quality specifications. |

|  | B) | Target conformance for performance quality. |

|  | C) | Conformance with specific management goals |

|  | D) | High, but achievable levels of quality conformance |

|  | E) | Relative quality conformance. |

|

|

|

| 7 |  |

The robust quality approach is related to the concept of: |

|  | A) | Goalpost conformance. |

|  | B) | Absolute conformance. |

|  | C) | Cost of quality. |

|  | D) | Prevention costs. |

|  | E) | Nonconformance costs. |

|

|

|

| 8 |  |

A diagram that organizes a chain of cause and effect to identify quality issues is called a: |

|  | A) | Goalpost chart |

|  | B) | Pareto diagram |

|  | C) | Control chart |

|  | D) | Fish-bone diagram |

|  | E) | Histogram |

|

|

|

| 9 |  |

A key tool for detecting poor quality include: |

|  | A) | Goalpost conformance. |

|  | B) | Lean manufacturing. |

|  | C) | Value streams. |

|  | D) | Cause and effect diagrams. |

|  | E) | Control charts. |

|

|

|

| 10 |  |

The objective of the Cost of Quality (COQ) Report is achieved when it: |

|  | A) | provides a baseline against which quality improvements can be measured. |

|  | B) | improves throughput. |

|  | C) | improves overall operating efficiency. |

|  | D) | identifies quality costs by department and manager. |

|  | E) | reduces standard costs in the plant. |

|

|

|

| 11 |  |

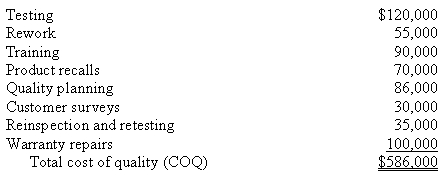

Herman Company had the following quality costs for 2010: <a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg::::/sites/dl/free/0078025532/966414/ch17_q11_1.jpg','popWin', 'width=NaN,height=NaN,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (26.0K)</a> <a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg::::/sites/dl/free/0078025532/966414/ch17_q11_1.jpg','popWin', 'width=NaN,height=NaN,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (26.0K)</a>

Sales for 2010 were $2,000,000.

What is the amount of appraisal costs? |

|  | A) | $120,000 |

|  | B) | $185,000 |

|  | C) | $65,000 |

|  | D) | $150,000 |

|  | E) | None of the above. |

|

|

|

| 12 |  |

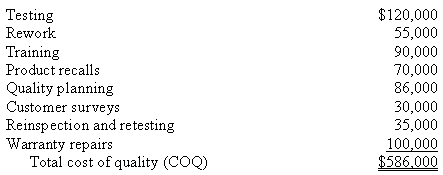

Herman Company had the following quality costs for 2010: <a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg::::/sites/dl/free/0078025532/966414/ch17_q12_1.jpg','popWin', 'width=NaN,height=NaN,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (26.0K)</a> <a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg::::/sites/dl/free/0078025532/966414/ch17_q12_1.jpg','popWin', 'width=NaN,height=NaN,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (26.0K)</a>

Sales for 2010 were $2,000,000.

What is the amount of external failure costs? |

|  | A) | $70,000 |

|  | B) | $170,000 |

|  | C) | $100,000 |

|  | D) | $135,000 |

|  | E) | None of the above. |

|

|

|

| 13 |  |

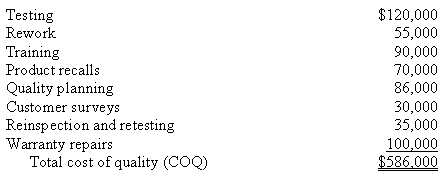

Herman Company had the following quality costs for 2010: <a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg::::/sites/dl/free/0078025532/966414/ch17_q13_1.jpg','popWin', 'width=NaN,height=NaN,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (26.0K)</a> <a onClick="window.open('/olcweb/cgi/pluginpop.cgi?it=jpg::::/sites/dl/free/0078025532/966414/ch17_q13_1.jpg','popWin', 'width=NaN,height=NaN,resizable,scrollbars');" href="#"><img valign="absmiddle" height="16" width="16" border="0" src="/olcweb/styles/shared/linkicons/image.gif"> (26.0K)</a>

Sales for 2010 were $2,000,000.

If Herman Company is able to reduce quality costs to 2.5 percent of sales, what is the likely effect on operating income? |

|  | A) | Increase by $586,000 |

|  | B) | Decrease by $50,000 |

|  | C) | Increase by $536,000 |

|  | D) | Decrease by $586,000 |

|  | E) | Increase by $50,000 |

|

|

|

| 14 |  |

Which of the following is an example of an external quality metric? |

|  | A) | Percentage of first-pass yields |

|  | B) | Number of customer complaints |

|  | C) | Cycle time efficiency |

|  | D) | New product development time |

|  | E) | Number of defective parts produced |

|

|

|

| 15 |  |

Studies have shown that lean manufacturing was being introduced by about ________% of companies surveyed, and that about _______% of the companies have achieved some mastery of the method. |

|  | A) | 80%, 40% |

|  | B) | 70%, 30% |

|  | C) | 60%, 20% |

|  | D) | 50%, 10% |

|  | E) | 40%, 5% |

|

|